Tomato ketchup is one of the world’s most popular condiments, and it can be found

in many households around the world. We have ketchup with burgers, fries, and just about anything that we can think of to complement our meals.

Heinz is the ketchup market leader in the U.S. and sells over 650 million bottles of ketchup around the world every year. Let’s take a tour of the Heinz European factory in Elst, Netherlands to see how the world-famous condiment is made.

Heinz Ketchup Factory: How Ketchup Is Made

Heinz process manager, Danielle Traa will be happy to take you on a tour of the Heinz ketchup factory. Here’s how ketchup is made:

Amazing!

“Here in Elst, we make sauces for the Kraft Heinz company. Our main product is ketchup. That’s 70% of what we do. We make about 1.8 million bottles of ketchup a day, and that relates to about 175,000 metric tons of ketchup a year.”

The ketchup-making process starts here, where crates of tomato paste weighing 1,300 kilograms are transported from the Heinz warehouse using automated forklifts. The crates are opened and then go to the paste dumper, where these huge rolling pins squeeze the paste out of the package.

After the paste has been extracted, it sits in a storage bin, where it’s mixed with water to give it a smoother consistency. This makes it easier to transport to the storage tank,

where it will sit until moving on to the ketchup kitchen.

This is our ketchup kitchen, and this is where we actually produce the tomato ketchup. Ketchup is made of five ingredients:

- sugar

- vinegar

- tomato paste

- brine

- secret spices (and love?)

The spices are dosed by hand. We dose everything, we mix it, and afterward, it goes into our process. The process is mainly about heating the ketchup and then cooling it down. Afterward, we fill it into the bottles.

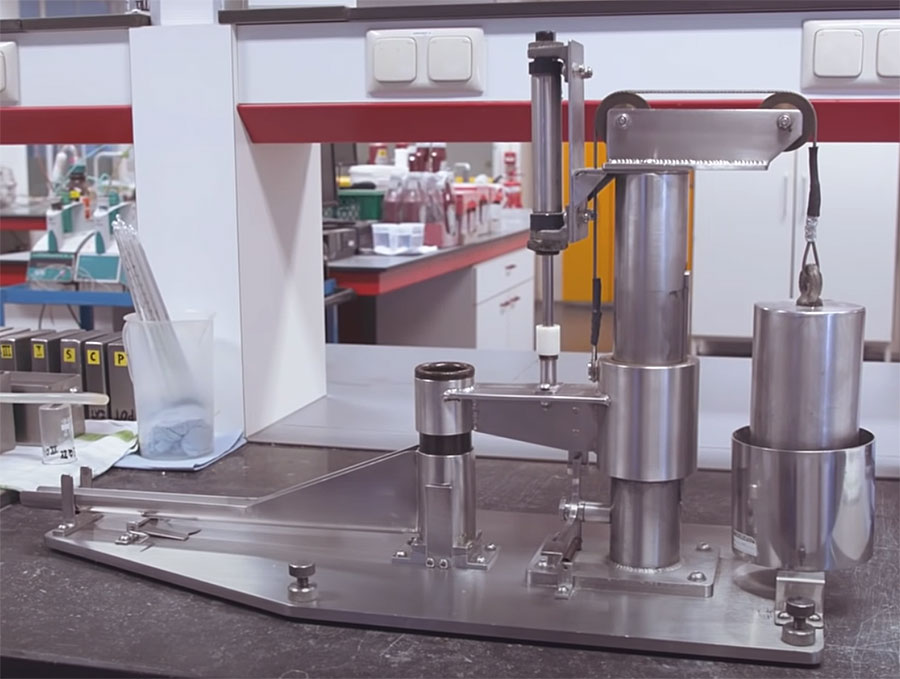

But before any ketchup can be shipped, each batch must be rigorously tested through this contraption, which Heinz calls, “the quantifier.”

The Ketchup Quantifier

This is the quantifier. (Not to be confused with the 1988 direct-to-tv movie, The Quantifier, starring Sylvester Stallone, haha!) It’s a method where we measure the viscosity of our Heinz tomato ketchup. It’s a methodology that we use in all our ketchup factories so that we compare the ketchup quality for all the factories.

What we do is we put a certain amount of ketchup inside the quantifier, we release it, and we measure how fast it has traveled after 10 seconds. 10.5, within range. It’s a special method designed by Heinz.

The ketchup cannot move faster than 0.028 mph. If it has traveled too far, we have to block it, cannot sell it. If it’s within the range, we can release it.

*Related: McDonald’s Burger and Bun Factory

The Ketchup Making Process Continues

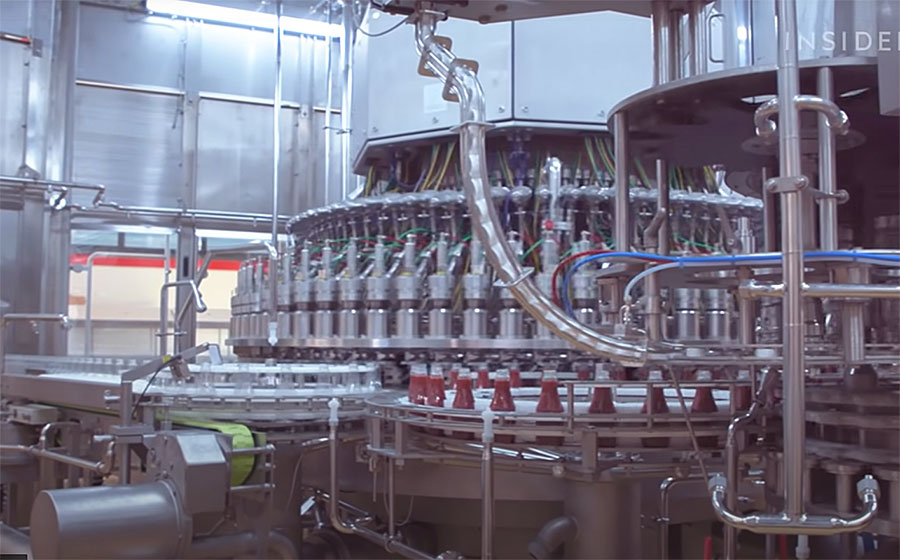

It’s for the empty bottles. They go into the filler. We have 70 filling hats. It’s a filler that works by weight.

So, a bottle comes in, we check the weight of the empty bottle, we fill it to the proper weight with ketchup, and then we check again if we reached the filling weight. The boxes with caps are emptied at the bottom floor by the operator and transported upstairs.

Did you know: There are about 255 workers employed at the Dutch Heinz factory in Elst, Netherlands

Ketchup Bottles Get Labeled

Upstairs, we make sure the caps are put in the right position and go to a single row of caps so that we can position them properly on the bottle in the filling machine.

And for this bottle, we have three labels.

So, we have a neck label, a back label, and a front label. These labels are self-adhesive, so we don’t need any glue for them.

After the ketchup labeler, we go to a tray packer, where we get a tray from the bottom. We fold it around the bottles. After that, put a shrink wrap around it and make sure the bottles are tight and packed in the tray.

From the tray packer, we go to the palletizer, where a robot puts the trays in the right position. And from the right position, we make a layer for layer on the pallet. After that, we put shrink-wrap around it. Then, the ketchup is ready to be shipped from Elst, Netherlands to 72 countries around the world.

*Related: McDonald’s Portions Over the Years

Heinz Ketchup History

Now that we’ve seen how its iconic ketchup is made, how did Heinz become the prominent brand it is today? Here’s a brief history of Heinz ketchup.

Heinz was founded in Pittsburgh in 1869 by a 25-year-old named Henry John Heinz, who began his business by selling his mother’s horseradish recipe. Over the years, Heinz expanded his catalog, selling pickles, vinegar, and eventually tomato ketchup, which launched in 1876.

It was a roaring success, and in 1886, the company began shipping the sauce to the UK. Following the overwhelming popularity of Heinz ketchup, Heinz started producing 13 million bottles a year and exporting them all over the world. This explains why you’re never too far from a bottle of Heinz tomato ketchup!

*Related: $4 WSJ Subscription? – Featured on linktree here